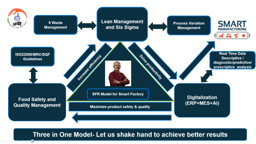

Traceability through AI

The manufacturing industry is experiencing significant growth, and smart manufacturing represents the latest evolution in this sector, with the potential to transform the entire landscape. Various technologies have been introduced to enhance manufacturing processes and steps, making them more efficient than ever before. One fundamental requirement for businesses, customers, users, and regulatory authorities is traceability. Artificial Intelligence (AI) is one of the key technologies assisting the industry in establishing effective traceability protocols.

AI is increasingly transforming food traceability systems by providing real-time information and making processes more efficient, accurate, and transparent. Here are some ways AI is being utilized in food traceability:

- Data Integration and Analysis:

AI can process vast amounts of data from various sources, providing real-time insights into the entire food supply chain. This capability allows for improved tracking of food products from farm to table, identifying potential risks, and ensuring compliance with regulatory requirements.

- AI and Blockchain:

Through integration with blockchain technology, AI enhances the transparency and security of traceability systems. While blockchain records track transactions, AI analyses these transactions to detect patterns and discrepancies. This integration is particularly useful for identifying counterfeit products, ensuring the authenticity of ingredients, and preventing food fraud.

- Predictive Analytics:

AI-driven predictive models can predict potential disruptions in the supply chain, such as transportation delays, equipment failures, or adverse weather conditions that may affect the availability or quality of food products. By predicting these risks, companies can proactively implement corrective measures to ensure food safety and maintain supply chain integrity.

- Smart Labelling:

AI-powered smart labels can track the real-time conditions and associated parameters of food products, such as temperature, moisture, source of raw materials, humidity, and freshness. For instance, sensors embedded in packaging can detect if a product has been exposed to unsafe temperatures during transport. AI analyses this data and provides actionable insights, enabling better decision-making for organizations and quality control teams.

- Image Recognition and Machine Learning:

AI-based image recognition tools can identify the origin of food products by analysing their physical characteristics, such as size, shape, colour, and texture. Machine learning models can be trained to detect specific patterns in agricultural products, assisting in tracing them back to their source and ensuring compliance with quality standards.

- Quality Control and Food Safety:

AI helps monitor and manage food safety risks by continuously analysing data from sensors, cameras, and other monitoring devices. It can flag deviations at critical control points (e.g., temperature, hygiene practices), assisting with immediate corrective actions. In smart manufacturing, AI can integrate with IoT devices to track real-time production data, ensuring that each product batch meets regulatory and safety standards.

- Improved Supply Chain Visibility:

AI provides end-to-end visibility into the supply chain, helping stakeholders identify bottlenecks, inefficiencies, and areas where food safety may be compromised. By analysing this data, AI can recommend improvements to processes, reduce food waste and losses, and ensure the timely delivery of fresh products.

- Consumer Transparency:

Consumers are increasingly demanding transparency regarding the origin, production methods, and ingredients of their food. AI-driven systems enable food companies to provide more detailed information to consumers, such as where the food was grown, how it was processed, and how it reached the store, often accessible via QR codes or apps.

- Regulatory Compliance:

AI systems assist in streamlining compliance with food safety regulations by ensuring accurate documentation and tracking of every step in the supply chain. AI can automate audits, trace non-compliant products, and generate reports for regulatory authorities, saving time and reducing human error.

Summary: AI

- Increases food safety management through the rapid identification and mitigation of contamination risks.

- Assist in enhancing consumer trust by offering more transparent and reliable product information.

- Helps in cost savings by optimizing the supply chain, reducing waste, and avoiding product recalls.

- Traceability assisted using AI-driven technology provides a competitive edge in food manufacturing, ensuring safer products, better compliance, and a more resilient supply chain.

- Many more….

Please sign in or register for FREE

If you are a registered user on The FSQ Network, please sign in