The Role of MES in Digital Transformation: Key Considerations for Project Planning

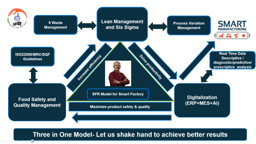

Digital transformation streamlines and optimizes manufacturing processes, shifting operations from reactive to proactive while enhancing speed, agility, flexibility, and responsiveness. Among the many tools supporting digital transformation, Manufacturing Execution Systems (MES) form the foundation, enabling collaboration, increasing productivity, and improving manufacturing quality, consistency, and predictability.

When planning an MES project, several factors must be considered to minimize delays, control costs, and prevent post-implementation issues that could lower staff morale—or, in the worst-case scenario, lead to the abandonment of the newly implemented system. One often overlooked aspect is the knowledge gap between IT experts and manufacturing processes, which can have significant implications if not addressed early.

Bridging the Gap Between IT Experts and Manufacturing Operations

During the project proposal phase, IT specialists from system providers typically visit manufacturing sites to gather information for refining or designing IT applications. While these experts possess strong technical skills, they may lack in-depth knowledge of manufacturing processes. This gap creates a risk of missing critical operational details, which can later result in inefficiencies, unexpected challenges, or misalignment with production needs.

Similarly, if internal users—the manufacturing teams and other stakeholders—fail to clearly define their requirements, particularly in terms of expected outcomes, data needs, information flows, and report formats, serious consequences may arise. Miscommunication or ambiguity can lead to misconfigured systems, inadequate reporting, and inefficiencies in production management.

Ensuring Project Success Through Balanced Expertise

To mitigate these risks, active engagement from both IT specialists and manufacturing teams is a critical success factor. A well-balanced project team should include:

- IT Experts in addition to a deep knowledge of MES and digital solutions, must have a good understanding of manufacturing processes and the importance of links between two or more than two processes.

- Manufacturing Professionals who understand operational workflows, data requirements, and reporting structures.

- Cross-functional Collaboration to ensure accurate, transparent, and comprehensive information is collected, covering all relevant processes in the supply chain.

By ensuring a holistic approach in the planning phase—where both technical and operational expertise are fully leveraged—organizations can increase the likelihood of a successful MES implementation, maximizing efficiency and long-term benefits in their digital transformation journey.

Advice is available if required.

Smart Manufacturing Champion

Syed Farhat Raza

Please sign in or register for FREE

If you are a registered user on The FSQ Network, please sign in