The Role of Digital Transformation in Food Manufacturing

The Significance of Digitisation in Food Manufacturing: Enhancing Food Safety, Quality, and Operational Efficiency

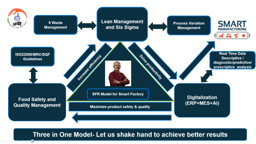

Digitisation is revolutionising the food manufacturing industry by enabling smarter, faster, and more reliable processes that directly impact food safety, product quality, and operational efficiencies. Integrating digital technologies such as IoT sensors, real-time data analytics, Manufacturing Execution Systems (MES), and AI-driven monitoring systems creates a foundation for transformative improvements across the entire food production lifecycle.

Food Safety:

Digital tools enable continuous monitoring of critical control points, environmental conditions, and equipment performance with unparalleled precision and speed. Automated alerts and traceability systems ensure immediate detection and response to contamination risks or deviations from safety protocols, reducing the likelihood of foodborne illnesses and recalls. Blockchain and digital traceability enhance transparency and accountability across the supply chain, ensuring compliance with stringent food safety regulations.

Quality Assurance:

Digitisation facilitates consistent product quality by enabling real-time monitoring and control of production parameters such as temperature, humidity, ingredient ratios, and processing times. Data-driven insights help identify variations or defects early, allowing corrective actions before products reach consumers. Advanced analytics also support continuous improvement initiatives by pinpointing root causes of quality issues and optimising recipes or processes for superior outcomes.

Operational Efficiency:

Digital systems streamline manufacturing workflows by automating routine tasks, minimising manual errors, and optimising resource utilisation. Real-time visibility into production performance, inventory levels, and equipment status empowers decision-makers to reduce downtime, improve yield, and manage supply chains more effectively. Furthermore, predictive maintenance driven by data analytics helps prevent unexpected equipment failures, lowering maintenance costs and enhancing overall productivity.

In summary, digitisation in food manufacturing is a strategic enabler that safeguards consumer health, guarantees product excellence, and drives cost-effective operations. Companies embracing digital transformation position themselves to meet evolving market demands, regulatory requirements, and sustainability goals while building trust and competitiveness in the global food industry.

Please sign in or register for FREE

If you are a registered user on The FSQ Network, please sign in