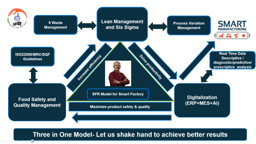

Flow Chart and Smart Manufacturing Project

Projects are normally supported by project proposals giving the complete details on purpose, resources required, timeline for project completion and expected outcome etc. Generally, the majority of the part of the plan consists of text-based information and, some figures in table and graphic form etc; In most cases, the proposal serves as a good guiding document. However, during the Smart Manufacturing Project, the use of flow charts worked very well in maintaining the clarity of the project information, avoiding mistakes and preventing the situation of repeating an activity or working to correct a mistake thus saving time and additional project cost. Especially, it was quite helpful in installing the hardware and equipment at the correct location for use. So the use of flow charts is not confined to HACCP only, but it can used as a tool in project management.

Guidance is available if required.

Please sign in or register for FREE

If you are a registered user on The FSQ Network, please sign in